Heating Oil Tank Maintenance Tips

Extending the Lifespan of Your Heating Oil Tank:

Maintenance Tips and Replacement Intervals

There are many households that are equipped with a heating oil tank which provides them with warmth during the coldest months of the year. Regular maintenance of the equipment and timely replacement of its parts are essential if one wishes to ensure its optimal performance as well as prevent potential problems. The following blog post describes how often you should replace your heating oil tank and provides valuable tips on how you can extend its lifespan in order to get the most out of it. In order to maintain your tank’s longevity, maximize its efficiency, and keep your home comfortable for many years to come, you should follow these guidelines. By doing so, you will be able to maximize the lifespan of your tank.

Regular maintenance is also important to keep your tank working properly. This includes checking the tank for leaks, cleaning the burner, and checking the fuel lines. Additionally, it is important to schedule regular inspections to ensure everything is in working order.

How often should you replace your heating oil tank?

There are several factors that can influence the lifespan of a heating oil tank, including the material, the quality of the installation, and the method by which it is maintained. As a general rule of thumb, it is recommended to consider replacing your tank every 15 to 20 years as a general guideline. The older a tank becomes, the more likely it will be to experience corrosion, leaks, and structural weakness, which can pose a safety hazard and lead to expensive repairs. An inspection by a qualified professional is a good way to determine the condition of your tank and whether or not it needs to be replaced. In order to comply with local regulations, be sure to familiarize yourself with the specific timeframes that may be required for the replacement of your tank. Having a properly maintained heating oil tank is essential for the safety of your home and those around you. Regular inspections and maintenance are important to keep your tank functioning properly. It is important to act quickly if any signs of corrosion or leaks are detected.

Maintenance tips for a longer-lasting heating oil tank

To extend the lifespan of your heating oil tank, proactive maintenance is key. Here are some essential tips to keep in mind:

Regular inspections:

In order to ensure that your tank is in good working order, you should have an annual inspection performed by a certified professional who can assess the tank’s condition, check for corrosion, and ensure that all of the components are functioning properly. The professional should also check for leaks, inspect the tank’s piping, and ensure that it is properly sealed. They should also test the safety equipment and make any necessary changes. They should provide a report with their findings and recommendations.

Monitor oil levels:

Regularly check the oil level in your tank and schedule heating oil refills to prevent the tank from running dry. As a result of an empty tank, sludge and sediment will build up, accelerating corrosion as time goes by. This can shorten the lifespan of the tank, resulting in costly repairs and replacements. Additionally, an oil leak can cause environmental damage and contaminate groundwater.

Keep the area clean:

If there is any debris, vegetation, or objects around the heating oil tank that could trap moisture or cause it to rust, it must be removed. The tank should be properly ventilated, and it should be accessible to inspection and maintenance so that the tank can be inspected.

Check for leaks:

Ensure that your heating oil tank is routinely inspected for any signs of leaks, such as stains, odors, or an unusually high rate of oil consumption. As soon as you find a leak, take immediate action to prevent environmental contamination and property damage. Contact the professionals as soon as possible to arrange for repairs. Clean out any spilled oil with the proper equipment. Document the accident and report it to your local authorities.

Install a tank protection system:

It may be a good idea to install a tank protection system, such as a tank tray or electronic leak detection system, in order to protect the tank. As a result of these devices, an additional layer of safety can be added, and leaks can be detected at an early stage in advance. This can help to avoid unnecessary environmental damage, as well as costly repairs. Additionally, it can help to extend the life of the tank, as any potential issues can be addressed quickly.

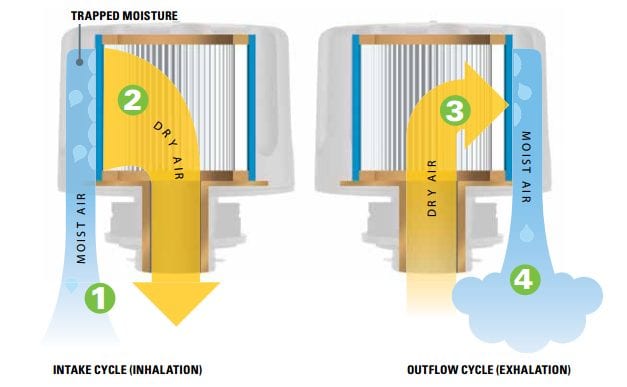

Monitor water accumulation:

It is possible for water to accumulate in your heating oil tank due to condensation, which speeds up the corrosion process. It is important to keep an eye out for water accumulation and to consider the installation of an absorbent pad or a water drain to mitigate the problem.

Signs indicating the need for immediate heating oil tank replacement

You can extend your heating oil tank’s lifespan significantly with regular maintenance, but certain signs may indicate it needs to be replaced immediately.

Here are some signs that your heating oil tank may need to be replaced:

Corrosion visible in the tank, such as rust or holes.

The tank leaks or spills oil frequently.

The tank is more than 15-20 years old.

Regulations and safety standards are not met by the tank.

Buildup of sediment or sludge inside the tank.

Damage to the structure, such as bulging or sagging.

Tank support or fittings deteriorated.

By following these maintenance tips and adhering to recommended replacement intervals, you can maximize the lifespan of your heating oil tank and ensure its safe and efficient operation. Regular inspections, proper maintenance, and prompt replacement when necessary will contribute to a reliable and long-lasting heating system for your home. To extend the lifespan of your heating oil tank, proactive maintenance is key. Regular cleaning and inspection of the tank should be done to detect any potential issues. Additionally, the heating oil tank should be filled only when it is full, and the tank should be drained when not in use. The tank should be refilled regularly to ensure that it is full and ready for use. We hope these tips are helpful in your experience with a heating oil tank and thank you for choosing Star Oilco as your preferred heating oil provider for the Portland area!