Renewable Diesel as a Major Transportation Fuel in California

STAR OILCO HAS RENEWABLE DIESEL FOR YOUR FLEET

In the Pacific Northwest we have gone from a complete scarcity of Renewable Diesel availability to several players having terminal positions and this next generation sustainable fuel being readily available. Star Oilco is ready to serve you with renewable diesel in several blends to meet both your fleet’s financial and carbon budgets.

For years California has lead the west coast with availability of renewable diesel and various blends with both petroleum diesel and biodiesel fuels. This experience is available in the research paper below to help inform your fleet in making decisions about de-carbonizing your fleets.

IS RENEWABLE DIESEL WORTH THE ADDED COST?

Fleet managers fell in love with this exceptionally high quality synthetic diesel fuel. Cleaner and drier than your typical petroleum diesel quite a few believers are willing to pay a large premium for this fuel. There are hardcore supporters of this fuel and it’s overall ability to reduce operational cost in far excess of it’s added cost. Which raises the next question. Is it superior to petroleum diesel?

IS RENEWABLE DIESEL SUPERIOR TO PETROLEUM DIESEL?

The answer points to yes based on initial experience rating the fuel on real world performance, fuel mileage, emissions system maintenance costs, and the much lower CO2 emissions.

The whitepaper shown is probably the most in depth resource for a fleet seeking to understand the potential of renewable diesel for its own use.

Renewable diesel is a next generation diesel fuel. It has a low CO2 footprint similar to biodiesel, yet it is a high performance fuel that reduces down time and maintenance in urban stop-and-go fleet use. Long story short, it is an impressive fuel solving many problems associated with modern clean diesel engines.

Given the newness of this fuel along, with the few producers of it, there is a real lack of in depth research on the subject.

If you have any questions about Renewable Diesel please feel free to contact us.

RENEWABLE DIESEL AS A MAJOR TRANSPORTATION FUEL

This white paper is the most in depth examination of Renewable Diesel operating in the real world. It covers a complete view of the product from the perspective of both fleets operating it and regulators seeking to reduce emissions. In our experience this is the most complete document you are going to find to advise a fleet considering using R99 Renewable Diesel.

Whitepaper – Renewable Diesel as a Major Transportation in California: Opportunities, Benefits, and Challenges.

Whitepaper that Gladstein, Neandross and Associates produced for the Bay Area Air Quality Management District and South Coast AQMD.

This report reinforces the manufacturers of renewable diesel’s statements and many anecdotal statements from fleets using the fuel. Renewable diesel sees superior performance in both emission reduction and performance in existing diesel technology. It is a cleaner burning and lower CO2 fuel that also contributes to a lower cost of vehicle maintenance.

According to this August 2017 report, California was on course to see approximately 250,000,000 gallons of R99 fuel sold in the state that year. This is a world-shaking volume of a next generation biofuel. With these readily adopted volumes, no doubt more product will be finding its way into the marketplace. The report cites a CARB expectation of the California Renewable Diesel market growing to over 2,000,000,000 (that’s BILLION) gallons in the next decade.

- Also see the US Department of Energy’s Alternate Fuel Data Center’s page on Renewable Diesel.

- Other articles by Star Oilco on renewable diesel:

- Cummins OEM Statement About Renewable Diesel

- Audi Develops Renewable Diesel Process

- Europe Leads the Way in Renewable Fuel Usage

- Oregon Helps Advance Renewable Diesel

- Mack and Volvo OEM Approval for Renewable Diesel

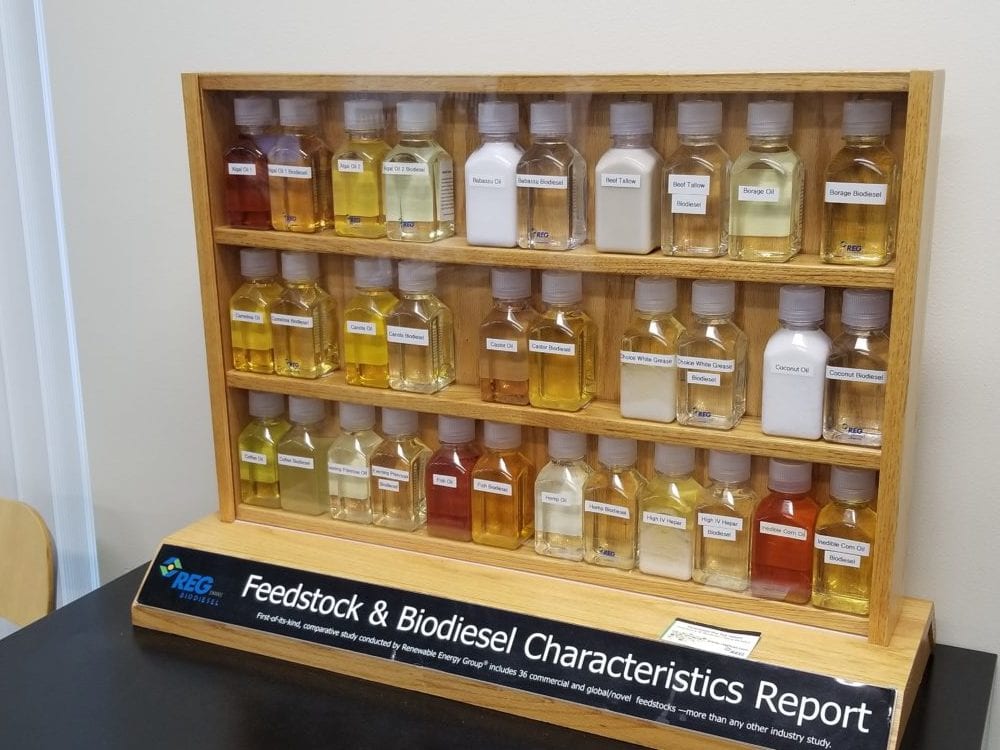

- Renewable Energy Group’s Renewable Diesel webpage (REG is the largest producer of R99 in the United States)

- Renewable Energy Group’s Ultra Clean Diesel webpage (REG’s 80% Renewable Diesel and 20% Biodiesel the lowest CO2 diesel in existence)